Fun & effective EPA 608 practice test tool to pass with flying colors

All-in-one platform with everything you need to ace the EPA 608 on your first attempt

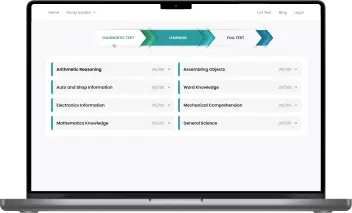

Clear and Thorough Learning Path

Proven EPA 3-step Practice Formula

After our 100,000+ users' success stories, we developed a 3-step strategy to provide you with the most precise and in-depth learning path while minimizing your prep time.EPA 608 Diagnostic Test

First, take this short test and get your detailed report showing your strong and weak areas. Save your time by concentrating on what is in demand.Learning

With quick, bite-sized learning techniques and a detailed study guide for each EPA 608 section, you can really strengthen your weaknesses (from step 1) and boost your scores.EPA 608 Full Test

The last step for your preparation is taking our full EPA 608 practice tests and seeing how far you've come since the beginning. Repeat the 3-step formula until you are satisfied with your results!Ready to start?

Thousands of EPA 608 users already accomplished their goals.NOW it’s your turn!

What You Get

All-in-one platform

A complete EPA 608 Prep Platform, including a diagnostic test, detailed study guides for all topics, practice questions with step-by-step explanations, and various full simulator tests.

Questions nearly identical to those in the real EPA 608 test

All questions are categorized into the specific sections as on the real EPA 608: Same format & same difficulty!

Best for the busy

Easily & quickly grasp all the knowledge with our unique learning technique. And you can learn anytime, anywhere on any devices, even with a few free minutes.

Practice while having fun

Learn and play! Complete round-by-round to reach your daily achievement and make progress on your learning journey!Featured on

What our users are saying

Over 50,000 aspiring American candidates use EPA 608 monthlyEPA 608 Exam Overview in 2024

In order to pass the EPA 608 test, you can consider taking our EPA 608 Practice Tests. First of all, let's find out about the EPA test.

EPA certification is now considered one of the most prestigious and popular certifications in the field of chemical handling engineers. Given the characteristics of this industry, successfully passing the EPA certification exam is required. In this article, we will help you find out every aspect of this certification.

What is an EPA certification?

In order to be certified by the EPA (which stands for the US Environmental Protection Agency), it is required for the technicians to show their understanding of the many laws and regulations that govern the handling of HVAC chemicals, such as R-22 and R-410A, used in air conditioners and heat pumps. Maintenance, servicing, repair, or disposal of equipment such as air conditioning and heating installations, which often use ODS refrigerants R-22 and R-410A, now requires certification under the Clean Air Act. This qualification is for technicians who have the responsibility for maintaining, servicing, or repairing both low and high-pressure equipment and small appliances and is the maximum position of certification available.

The EPA 608 certification has four levels. They're:

- Type 1: This module provides small items including refrigerators, water dispensers, and window air conditioning systems.

- Type 2: Type 2 certification includes high-pressure refrigerant service and disposal. Residential air conditioners, heat pumps, and supermarket refrigeration are all examples of this kind of technology.

- Type 3: Equipment that utilizes low-pressure refrigerant, such as chillers, may be serviced or disposed of under the Type 3 certification. The universal certification includes all of the equipment that falls within the categories of type 1, type 2, and type 3.

The equipment and chemicals you operate with may need composing besides the 608 certifications. Among them:

- 609 technical certification: Motor vehicle air-conditioning system (MVAC) technicians are eligible for the 609 accreditation. 609-certified technicians are well-versed in automotive refrigerant regulations and suitable refrigerant recovery methods.

- R-410A technical certification: In comparison to other refrigerants, R-410A is employed at substantially greater pressures. Additionally, R-410A and other comparable refrigerants have unique safety difficulties and concerns, thus manufacturers frequently prefer that personnel who handle them have specialist certification.

Who needs an EPA certification?

All technicians who operate with refrigerants and have the potential to release them into the air must be certified by the EPA under the Clean Air Act. Maintaining and repairing refrigerant equipment may result in an employee releasing potentially harmful amounts of refrigerants, such as when hoses are attached or removed from the equipment, or when the refrigerant is added, removed from, or disposed of. During their apprenticeship, trainees do not need to be certified as long as they are closely supervised by a trained technician. In terms of EPA certification, there is no need for recertification or renewal.

What are the advantages of becoming EPA-certified?

ODS, which may be devastating to the atmosphere and all life on Earth once emitted into the surroundings, should only ever be addressed by specialists who have taken comprehensive EPA instruction. Oxygen-depleting substances (ODS) may harm our planet's ozone layer, which shields us from harmful Ultraviolet radiation from the sun. The quantity of ODS discharged into the atmosphere may be reduced by proper ODS treatment. Ozone layer strengthening and UV radiation reduction minimize the risk of skin cancer in humans and harm to plant and animal life, respectively, as a result of this.

Section 608 Technician Certification

Section 608 of the Clean Air Act mandates that technicians who maintain, service, repair or dispose of equipment that might leak refrigerants into the atmosphere be qualified. Section 608 Technician Certification may only be obtained by passing an EPA-approved exam. The assessments are tailored to the sort of equipment that the specialist is interested in working on. It is required for an EPA-approved accrediting agency to conduct the tests. No expiration date applies to Section 608 Technician Certification credentials. Universal Certification cannot be obtained by taking open-book exams for core certifications. To be eligible for Universal Certification, it is required for the candidates to successfully pass the core examination under the supervision of a moderator.

Technical work is defined by EPA rules under Section 608 of the Clean Air Act as any activity in which a "technician" participates, including but not limited to:

- The process of connecting and disconnecting hoses and gauges to and from an appliance in order to measure the device's pressure.

- Add or remove the refrigerant from a machine, as needed.

- A piece of equipment or tiny equipment that interferes with the integrity of a vehicle's air conditioning system.

- As long as they are under the supervision of a trained technician, apprenticeships are free from having to get a professional license.

Learn all EPA 608 test questions with our FREE EPA practice exam!

Definitions of Section 608 Terms

Appliance

Class I, Class II, or replacement refrigerant-containing devices, including any air conditioner, motor vehicle air conditioner, refrigerator, chiller, or freezer used for domestic or commercial applications. Each individual circuitry in a configuration with several circuits is treated as a single piece of equipment. According to the Environmental Protection Agency (which is popularly known as the EPA for short), this term encompasses all types of cooling and freezing equipment, with the exception of that which is purely military in nature.

Apprentice

An apprentice in equipment administration, servicing, repairing, or disposing of who is presently enrolled with the US Department of Labor's Office of Apprenticeship is eligible for this benefit.

Major repairs, servicing, or maintenance

Appliance compressors, condensation, evaporation, and/or auxiliary heat exchanger coil replacement for servicing or replacement.

Motor Vehicle Air Conditioner (MVAC)-like appliance

Appliances for cooling the driver or passenger's compartment in off-road machines, such as farming and commercial trucks, employ intermittent pneumatic decompression. Devices that use HCFC-22 are not included in this specification (also known as the R-22 for short).

Installing an equipment

Refrigerant leaks may occur during any servicing, maintenance, or repair of a refrigeration unit. No "entrance" is required to connect and detach hoses and gauges to and from the appliance in order to monitor pressures inside the equipment and to add or recuperate refrigerant.

Reclaim

For the purpose of reprocessing recovered refrigerant to AHRI Standard 700-2016 cleanliness and to validate this purity using the analytical methods given in the standard, AHRI recommends the following: Specialized equipment, such as that required for reclamation, is not readily accessible at every construction site or vehicle repair shop. A generic Elementalist or the refrigerant producer are the two options for the specialist for the purpose of returning the refrigerant once it has been recovered.

Recover

Recovering is the act of taking off a refrigerator's refrigerant and storing it in a separate container without first testing or processing the contents.

Recycle

If you're talking about a refrigerant, recycling entails removing the refrigerant from an appliance and cleaning it so that it may be re-used inside that same owner's equipment. Most recovered refrigerants are cleaned utilizing oil separation and single or repeated runs through devices such as replaceable core filter-driers, which remove moisture, acidity, and particulate matter from the fluid. Car air conditioner refrigerant may be recycled on-site and subsequently charged into another vehicle under Section 609 of the Clean Air Act.

Circuit of refrigerant

There are components of a refrigerator that contain refrigerant, even if they are just divided by internal valves.

Technician

An appliance (excluding MVACs) whose refrigerant circuit integrity might be reasonably anticipated to be violated during the process of maintenance, service, or repair of an appliance (except MVACs) In addition, the term "technician" includes anybody who may possibly be anticipated to damage the continuity of the refrigerant connection when dismantling equipment (excluding small appliances, MVACs, and MVAC-like appliances) and thereby release refrigerants into the surroundings.

Attaching or removing hoses and gauges to/from the appliance, adding or withdrawing refrigerant, adding or removing components, and cutting the refrigerant line are all possible activities that might compromise the circuit's integrity. A refrigerant circuit may be safely maintained by doing routine maintenance such as painting, rewiring, changing insulation on a pipe, and tightening bolts and nuts. Refrigerants should not be released from appliances that have been adequately evacuated, even if the action involves adding more to the device. Installers, contractors, in-house service professionals, and owners and/or operators are all examples of technicians.

Section 608 Technician Certification Programs

The EPA Section 608 technician certification examination may be taken at any of the institutions here on site. These programs have a number of key features to take into account:

- For the most part within the Section 608 Technician Certification, Type 1 programs allow students to take exams on-site. These programs include mail-in assessment as an option.

- The organization's headquarters is situated at the locations and phone numbers indicated below. There are several programs that have testing centers all around the nation. You'll be able to find out where each project's testing takes place if you ask. If you don't want to visit a testing place, several programs provide virtual or remote testing.

- Those programs indicated by an asterisk (*) are only meant for company workers.

- No training prepared programs or resources are vetted or approved by the EPA. These programs' accreditation certifications are still effective for the time period in which they were authorized.

Test Topics of the Section 608 Technician Certification

To get Section 608 technician certification, it is required for the candidates to successfully complete an EPA-approved examination. For each of the 4 levels of the Section 608 Technician Certification Test, we've listed some of the exam subjects that will be addressed. As a reminder, universal certification includes themes relevant to certifications in general, as well as those in particular.

EPA 608 Core Exam

- Chlorine's degradation of the atmosphere

- Respirable refrigerants containing CFCs or HCFCs have chlorine added to make them more environmentally friendly.

- CFC, HCFC, and hydrofluorocarbon (which is also known as the HFC for short) chemical classification

- To put it another way, CFCs are thought to have a larger ozone-depletion potential (ODP) than HCFCs, who in turn are thought to have a higher ODP than HFCs.

- An awareness of how various forms of refrigerants affect the atmosphere

- Ridiculously high loss of ozone has both environmental and economic consequences.

- The role played by CFC and Hydrofluorocarbons ( HFCs in the atmospheric ozone hole)

- Clean Air Act and Montreal Protocol

- Phase-out deadline for CFCs

- The date of R-22's demise

- Servicing facilities have a no-venting rule

- Montreal Protocol

- Disposal venting is not permitted

- Alternative compressed gasses are prohibited from being used.

- The maximum penalty for violating the Clean Air Act Montreal Protocol is $1 million

- Section 608 Regulations

- High- and low-pressure chlorofluorocarbons: terminology and classification

- Framework vs conscience rehabilitation equipment description

- Designation of the regulated components

- Machinery for reutilization must be certified by a 3rd party.

- AHRI Standard 700-2016 for recycled refrigerant is the mainstream technology for recovered refrigeration.

- The sales restriction

- Venting prohibition

- Substitute Refrigerants and oils

- The lack of "drop-in" substitutes

- Substitute refrigerants may not be compatible with many lubricants that had been used with CFC and HCFC refrigerants, as well as CFC and HCFC refrigerants

- The issue of fragmentation occurs when various mixture ingredients leak at various speeds.

- Refrigeration

- At what times in the cooling system do the coolant phases (vapor vs. solid) and concentrations change?

- Infrared thermometers (color codes, ranges of different types, proper use)

- Detection of Leaks

- 3 R's of Rhetoric

- Recovering

- Recycling

- Recycling

- Recuperation Methods

- Refrigerants must not be mixed.

- Indicators of a person's ability to bounce back (ambient temperature, size of recycling or recovery equipment, hose length, diameter, etc.)

- Dehydration Evacuation

At the conclusion of service, it is required for the system to be evacuated in order to remove any remaining excess moisture.

- Safety

- The dangers of refrigerant consumption (e.g., oxygen deprivation, cardiac effects, frostbite, long-term hazards)

- It is important to recognize the difference between "rehabilitation" and "expendable" canisters and to confirm that the latter is DOT-approved before using it.

- Compromising safety by over-filling gas cylinders

- The use of nitrogen rather than oxygen or compressed air for leak detection

- Nitrogen requires the use of a controller and a release valve.

- Shipping

Refrigerant containers need tracking numbers (refrigerant identification, DOT classification tag)

EPA 608 Type 1 (Small Appliances)

- Conditions for Recuperation

- An explanation of "small appliance" and its evacuation requirements prior to the year 1993 for small appliances with and without operating blowers

- Extraction criteria for small appliances with and without compressors that use recuperation equipment produced after 1993.

- Recuperation Methods

- Non - condensable substances may be identified by comparing the pressure and temperature of refrigerants.

- Methods to recovery refrigerant from small appliances with inoperative compressors utilizing a system-dependent or "passive" recovery mechanism (e.g., heat and violently hit the compressor, utilize a vacuum pump with a non-pressurized recovery container) (e.g., heat and sharply strike the compressor, use a vacuum pump with a non-pressurized recovery container)

- Recovering refrigerant from tiny appliances with malfunctioning compressors necessitates the installation of both high and low-side access valves.

- Need to activate operable compressors while recovering refrigerant using a system-dependent ("passive") recovery mechanism

- After the service is completed, the solderless access fittings should be removed.

- As an alternative to chlorofluorocarbon (CFC)-12, hydrofluorocarbon (HFC)-134a (often referred to as R-134a) (also called R-12)

- Safety

Decomposition of products of refrigerants at high temperatures

EPA 608 Type 2 (High-Pressure)

- Leak Detection

- Indicators of high transmission breakdown (excessive superheat, traces of oil for hermetic)

- Before replenishing or refilling machinery, leak testing is needed.

- Leak test gasses are ranked according to preference. R-22 (hydrochlorofluorocarbon-22) is a refrigerant having a halogen atom attached to the nitrogen atom.

- Repairing leaks necessitates the use of certain tools

- Allowed rate of refrigerant leakage in commercial and industrial process refrigeration

- Keeping track of leak repairs

- Repairing leaks that have a leak rate that is higher than the threshold

- Recuperation Methods

- Speeds up the healing process by removing the liquid at the beginning.

- Other ways to speed up the healing process exist (chilling recovery vessel, heating appliance, or vessel from which refrigerant is being recovered)

- When a fresh refrigerant is used in a recovery or recycling system, there are ways to minimize contamination and emissions.

- Wait a few minutes after achieving the appropriate recovery vacuum to check whether the system pressure increases (indicating that there is still liquid refrigerant in the system or in the oil)

- Conditions for Recuperation

For high-pressure appliances in each of the following conditions, there are evacuation requirements:

- Disposal

- A comparison of large and minor repairs

- Appliances with and without leaks

- Appliance (or component) weighing less than 200 pounds against one weighing more than that.

- Pre-1993 versus post-1993 recovery/recycling equipment

- Definition of "significant" repairs

- Refrigerant systems that hold more than 15 pounds of refrigerant cannot be recovered utilizing system-dependent recovery equipment

- Refrigeration

- How to recognize the kind of refrigerant used in various home products.

- High-pressure refrigerant pressure-temperature relationships [may use conventional temperature-pressure chart; be mindful of the requirement to add 14.7 in order to convert psig to psia]

- Refrigeration systems consist of receivers, evaporators, and accumulators, as well as the liquid or vapor form in which the refrigerant is stored

- The notion that retrofits using hydrocarbons are not permitted

- Safety

The American Society of Heating, Refrigerating, and Air-Conditioning Engineers (which is also popularly known as ASHRAE for short) Standard 15 prohibits the use of hermetic compressors in vacuum Equipment rooms.

What If Your Section 608 Technician Certification Card Gets Stolen

Section 608 qualified technicians may use this website to learn how to get a new certification card if they lose their old one. A lost or stolen certification card cannot be replaced by the Environmental Protection Agency (EPA).

Step 1: To begin, you need to find out whether or not the testing agency that gave your certification is still in operation. Verify the list of certification bodies that are still in existence.

- If this is the case, get in touch with the organization and request a new card. Cards issued by the organization must be kept in a database.

- Go to Step 2 if no.

Step 2: Next, do you have proof that you passed the Section 608 technician certification exam? If so, please provide it to us. Is there a copy of your missing card with you, or at a current or past employer?

- The organizations listed in the box below are interested in receiving a copy of your paperwork. The organization will provide you with a new certification card and keep a record of your accomplishments.

- Go to Step 3 if no.

Step 3: Did you get your certification from a company that has since closed its doors? Take a look at the list of certification bodies that have gone out of business.

- If so, please contact us.

- Is this the case? If so, go to Step 4.

Step 4: If you can't respond "yes" to any of the questions above, you won't be able to get a replacement card from the EPA or a recognized testing business. If you fail the Section 608 certification exam, you will have to repeat it. Visit the Section 608 Technician Certification programs page to identify testing companies that fulfill your requirements.

EPA certification is a challenging certification. Therefore, it is required for you to deeply understand all the related terms within this certification, and then carefully prepare for your studying process. Good luck and hope you can ace the EPA!

Why Should You Use Our EPA 608 Practice Test?

These are the benefits of using the EPA 608 Prep Test on our app:

- Hundreds of EPA 608 practice questions will help you improve your knowledge.

- Having a personal study plan

- Studying anywhere at any time even without an internet connection

- Practicing with 3 different test modes can help you level up quickly

- Experiencing cool dark mode

- No sign-up is needed. However, if you have an account, you can sync your data between the web and the mobile app.

Let's start your studying right now with our EPA 608 Practice Test!